To Reduce Plastic Pollution, Recycling Improvements Are Key

Introduction

There is significant concern in the United States regarding plastic pollution. With a general rise in plastic consumption comes a growing demand for policy responses that address associated waste and pollution. However, there is a lack of clarity on the connection between plastic consumption and plastic pollution. Specifically, even though plastic consumption is rising, plastic pollution caused by improper waste management is falling. This is why policies that improve waste-management practices are likely to carry greater benefit than those focused on consumption. This piece details what Americans can expect for the future of plastic use in the United States and explores policies that would help alleviate plastic pollution.

Plastic Use in America

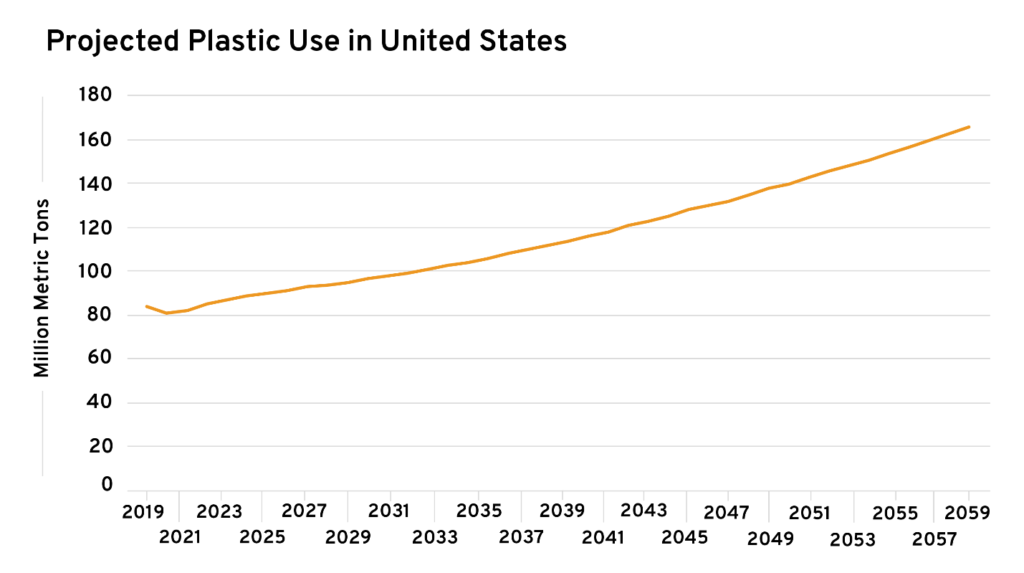

Plastics are used extensively in the United States, with a projected increase of approximately 90 percent through 2060.

Source: OECD Global Plastics Outlook

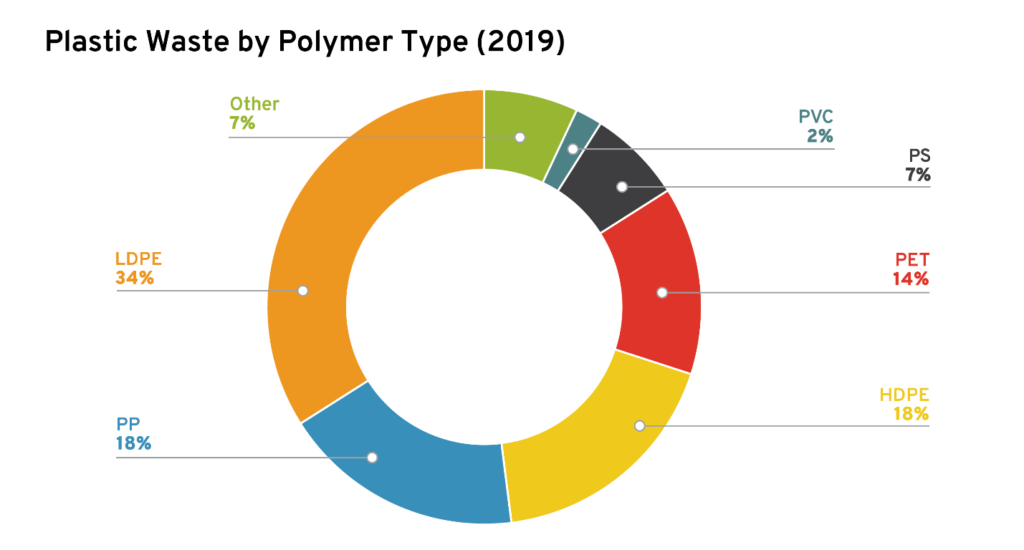

Plastics are used in a wide variety of applications, from packaging to containers to pipes and more. Although the term “plastic” is used broadly, Americans use several different types of the material. The following chart shows the volume of U.S. plastic waste by polymer type, and the accompanying table gives common examples of products that use those polymers.

Source: Quantification and evaluation of plastic waste in the United States

Source: The Old Farmer’s Almanac

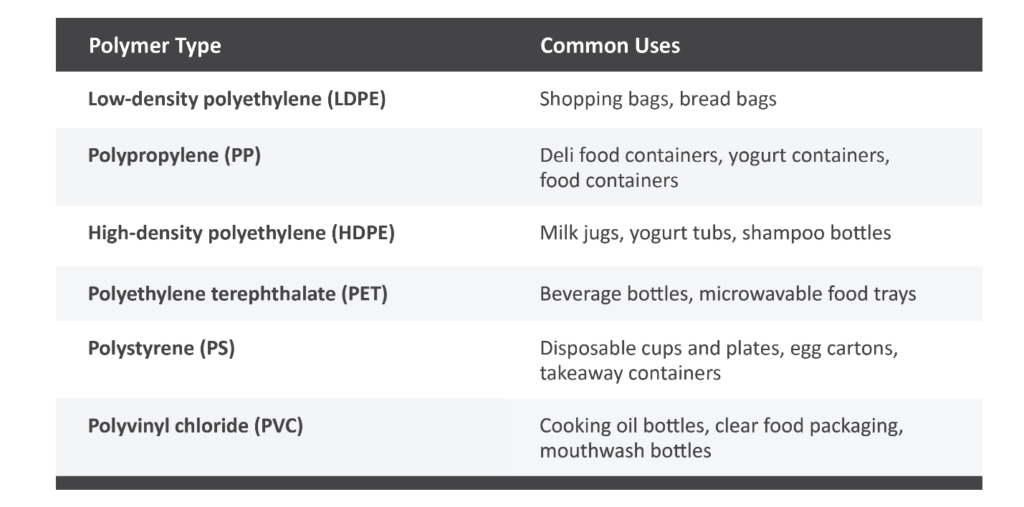

Generally, plastic use and waste can be categorized based on their application. This can give insight into exactly where plastic is used and reveal opportunities for better plastic waste management in the United States.

Sources: OECD.Stat, Plastic waste in 2019

In the United States, general plastic use per capita is projected to increase by 44 percent by 2050. But because plastics are used in so many different products, it is difficult to identify any single major contributor. Demand is anticipated to rise as well, due to single-use applications (such as takeaway containers and packaging), Americans’ growing reliance on shipping, the substitution of plastics for other materials (e.g., PVC pipes replacing metal ones), and other factors.

This means that while policies like prohibiting plastic straws or shopping bags may be popular, their ability to reduce plastic pollution is extraordinarily limited, as these uses represent only relatively small amounts of plastic use and waste. For example, plastic straws make up less than 1 percent of plastic waste, and plastic bags account for about 8 percent.

Plastic Waste and Recycling in the United States

Plastic waste refers to any end-of-life plastics, regardless of disposal method. Recycling is one disposal method; landfilling and incineration are others. Plastic pollution is caused by plastics that are improperly disposed of at the end of their life, such as uncollected litter or mismanaged plastic waste that may be dumped. Some analyses have erroneously conflated the terms “plastic waste” and “plastic pollution,” incorrectly concluding that because the United States has high levels of plastic waste, it must also have high levels of plastic pollution.

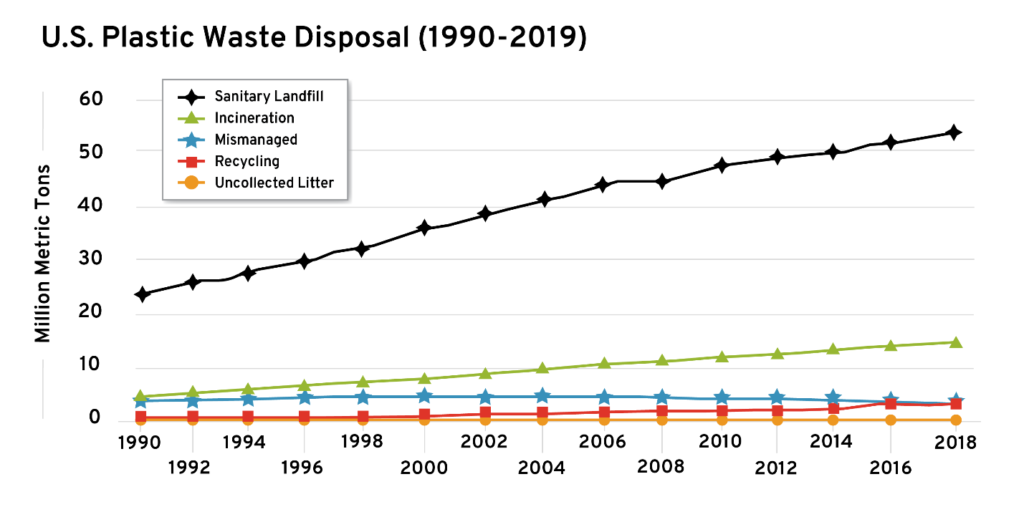

The following chart details total plastic waste in the United States over a 30-year period, organized by end-of-life destination.

Source: OECD.Stat, Plastic waste by region and end-of-life fate

The data shows that although plastics recycling has increased considerably—accounting for 4.5 percent of waste in 2019 compared to 1.3 percent in 1990—it remains very low. For comparison, the recycling rate for aluminum beverage containers is nearly 50 percent. The United States has also improved its management of plastic waste substantially, reducing overall mismanaged waste from 10 percent in 1990 to 3.4 percent in 2019. Thus, even though total plastic waste has more than doubled since 1990, the total volume of mismanaged waste has decreased from 3.1 million metric tons in 1990 to 2.5 million metric tons in 2019. Put another way, plastic use in the United States has increased, while plastics pollution has decreased. The data also reveals that mismanaged waste remains a far larger contributor to U.S. plastics pollution than littering.

However, the most important lesson from this data is that the vast majority of plastics in the United States end up in landfills. Recycling continues to be underutilized. While improved recycling practices would help efforts to reduce plastics pollution and the need to landfill waste, such practices have not materialized in the United States.

Challenging Economics Constrain Plastic Recycling

Waste management is a classic example of a collective action problem involving an externality. The marginal cost to an individual who chooses to dump plastic is zero, but the act of dumping plastic on the environment creates a cost that is borne by the public (an externality). If the cost of proper plastic disposal is lower than the cost borne by the public, then the act of dumping entails an economic cost that is borne by all. However, because the incentive to the individual is to pollute, it is efficient to impose penalties on those who dump waste in the United States.

The fundamental challenge with waste management is that most garbage is worthless. While collecting garbage incurs a cost, the material has no returnable value to the collector, meaning there is no natural private interest in waste management. This is why the public subsidizes waste collection—to create a financial incentive to reduce waste.

Some exceptions to the challenging economics of waste management do exist. Notably, some materials retain value after use. For example, the estimated value of a ton of recycled aluminum in 2018 was $1,432. This creates a financial incentive for recyclers, even without subsidy. At a typical materials recovery facility (MRF), aluminum accounts for about one-third of its revenues.

Plastics, though, struggle in recycling economics. When plastic is broken down, the polymer chain used to create it is shortened—meaning plastic can only be recycled a limited number of times (unlike aluminum, which can be recycled infinitely). As a result, virgin feedstocks for plastic production are more desirable than recycled ones. Additionally, the value of recycled plastic is low compared to aluminum; in 2018, a ton of recycled PET had a value of $309, whereas a ton of recycled HDPE had a value of $729. Virgin feedstocks for plastic are also sometimes cheaper; for example, when comparing resin prices for new production, the price of HDPE virgin material in 2021 was half the cost of recycled material.

Another considerable challenge to recycling plastic is its wide array of applications, as it does not always come in shapes and sizes that are practical for MRFs to process. For example, plastic shopping bags are the most common contaminant to recycling streams because—even though the plastic from these bags is recyclable—typical MRFs cannot sort them automatically.

The current drive for increased plastic recycling is less about the economic utility it brings and more about public desire for recycling activities as a preferable alternative to landfilling in waste management. By contrast, industries are pushing to expand aluminum recycling and processing because of the high value of aluminum products discarded into landfills.

Essentially, plastic-recycling economics would benefit from a market dynamic closer to that of aluminum, where recycled material is desirable to consumers. With that in mind, new “advanced recycling” processes have emerged to produce infinitely recyclable plastic. These methods use pyrolysis to break down polymers into their base chemicals, leaving no functional difference between virgin and recycled material. Advanced recycling products can also be used to produce fuel, creating another potential market for plastic waste.

From a waste-management perspective, avoiding mismanaged plastic waste and reducing reliance on landfilling plastics is complicated by the fact that plastic-recycling opportunities are severely limited under current mechanisms and that most recycled plastic has low value. Greater use of advanced recycling would produce plastic feedstocks that are interchangeable with virgin ones. Expansion of policy mechanisms like deposit refund systems (DRSs) could also boost recycling by aligning incentives for recycling behavior and proper waste-management practices, even in the absence of functional private markets.

Policy Recommendations

Below, we present several relatively simple policy solutions that the United States and other countries could adopt to help address the growing global problem of plastics pollution.

Expand Deposit Refund Systems

DRSs work exceedingly well at bolstering recycling rates. Under a DRS, a person pays a fee for a container or recyclable product that is refunded when they deposit the item for recycling. States with DRSs have an average PET bottle recycling rate of 55.7 percent, compared to 16.1 percent in states without a DRS. Additionally, R Street research has found that, despite critiques that a DRS functions as a tax and reduces consumption, states with DRSs experience a higher consumption of materials eligible for redemption— indicating minimal economic impact on product consumption. Residents of DRS states also tend to prefer DRSs over other recycling mechanisms.

From the R Street perspective, a DRS is an appealing solution to many waste-management problems because it promotes consumer choices and creates market incentives that would not otherwise exist. For comparison, curbside recycling largely depends upon whether the person engaging in the recycling finds it convenient and worthwhile. Under a DRS, individuals are financially motivated to recycle. This captures a larger share of recycling opportunity and, importantly, allows consumers to voluntarily determine the value of recycling versus other forms of waste disposal.

Recycling rates for plastics are quite low across the United States, even for in-demand, easily recycled materials. Although PET, valued for its ability to produce bottles, is recycled more than all other plastics, it still only achieves a rate of 18.5 percent, and this exceptional rate is likely due to several states utilizing DRSs. HDPE, often used for bottles that may also fall under a DRS, have the second highest rate at 8.9 percent. While data indicates that DRSs boost recycling rates for a few plastics in a few regions, a large volume of mismanaged plastic waste remains.

Undoubtedly, greater DRS utilization would boost recycling rates for all eligible items as well as increase and improve incentives to avoid mismanaged plastic waste.

Help Municipal Waste-Management Programs Improve Recycling

Alternative recycling methods are relatively nascent, and few municipalities have experimented in advanced recycling or alternative methods of managing traditionally difficult-to-recycle plastic waste. The federal government already facilitates grants from the U.S. Environmental Protection Agency (EPA) aimed at reducing air and water pollution, improving environmental education, and supporting environmentally relevant research. To the extent that these grants are already in place, it would make sense to expand these efforts to cover improvements in plastic recycling.

EPA efforts to improve plastics-recycling practices are especially important due to a lack of consensus among experts as to the potential benefits of advanced recycling. One study from the National Renewable Energy Laboratory determined that advanced recycling was worse for the environment than using virgin materials, whereas a more recent study from Argonne National Laboratory (ANL) found the opposite, showing greenhouse gas emission reductions of 18 to 23 percent. The researchers from ANL’s study noted they were the only ones to assess multiple facilities in operation and that other studies looked at single facilities only. Because there is little published information applicable to the advanced recycling industry in general, this is an area in which EPA grants can improve understanding and target opportunities to improve efficiency and reduce pollution.

Improve Green Guides and Product Labeling

The Federal Trade Commission (FTC) is in the process of updating its “Green Guides,” which provide guidelines to companies as to what claims they can make about their products under certain conditions. One challenge regarding recycling has been inconsistent (and often misleading) labeling of products produced from recycled materials and their recyclability. Because consumers generally prefer to buy recycled or “green” products, producers have an incentive to meet Green Guide criteria.

One issue with existing Green Guides is that labeling a product as recyclable does not indicate the utility of the recoverable materials and may imply a nonexistent circularity of materials. For example, while Styrofoam containers are often labeled with the green “chasing arrows” symbol for recyclability, the material is not as easy to recycle as similarly labeled items like PET bottles or aluminum cans—and it cannot always return to its original use.

Additionally, the existing Green Guides do not offer sufficient recognition of material recovery from advanced recycling. Returning to the Styrofoam example, such material is recyclable under advanced recycling methods and should be considered recyclable, but it is also possible to produce Styrofoam via advanced recycled plastics. However, because resins produced from advanced recycling are mixed with virgin feedstocks, the Green Guides may not allow resulting products to accurately indicate they were made with recycled materials.

One possible solution is to credit products made with plastics resulting from advanced recycling through displacement. For example, California’s Low Carbon Fuel Standard (LCFS) credits renewable natural gas producers. But the natural gas consumed there is not the same as the gas molecules produced for LCFS compliance because it mixes with all the other gas once it enters the pipeline. Therefore, California credits end-use customers with the upstream displacement of fossil natural gas. A similar program could work for plastics, where off-takers of resins for plastics are credited for their displacement of virgin feedstocks upstream.

The current Green Guides do not enable these sorts of distinctions even though customers would likely find them valuable when determining their product preferences. Many customers are willing to pay a premium for products that are friendlier to the environment, so providing better information helps them make better purchasing decisions. This simultaneously enables better market function, as producers are motivated to capitalize on environmental benefits.

By contrast, unclear labeling information negatively affects market function, as consumers who wish to pay for a specific service or outcome—in this case, environmental benefit—are unable to do so because the information they need is either unavailable or too difficult to obtain.

Conclusion

Although the United States currently has relatively low levels of mismanaged plastic waste and plastic pollution, substantial concerns still exist regarding plastic utilization and potential plastic leakage. Because no single-use case of plastics offers an easy opportunity for material substitution, policy aimed at reducing plastic pollution would benefit from a shift in focus to plastic waste management and recyclability.

Opportunities abound for reducing plastic waste through policy. Three key opportunities are the expansion of DRSs, which would incentivize more plastic recycling; support for innovation and advancement of recycling processes, including advanced recycling practices that may reduce both plastic pollution and air pollution from plastics production; and updates to federal guidance on recyclability claims to give consumers better information as to what products are recyclable and how they can be used after recycling.

Overall, better information, consumer guidance, and the adoption of innovative materials-management practices represent significant opportunities to reduce plastics pollution in the United States, particularly because discrete policies like prohibiting specific uses are unlikely to make much of a difference in the country’s plastic utilization.